HDPE pipes for pressure sewage

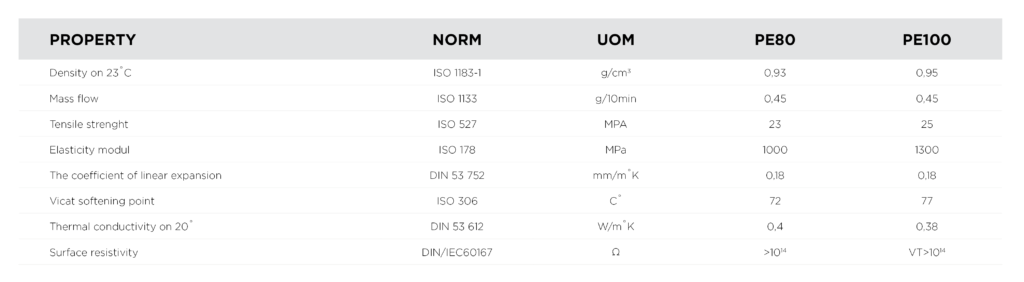

Peštan HDPE pipes for pressure sewage high-quality tubes are made from high quality polyethylene PE-80 and PE-100.

The advantages of this type of pipe compared to other materials is that due to its high flexibility and resistance to seismic shocks and shifting of the soil can be used for installation in areas where they can count on this situation. Bending radius of polyethylene pipes is 20 d. High resistance polyethylene on capturing deposits makes these pipes more suited for use in pressure sewage then other pipe materials.

Polyethylene pipes for pressure sewage are stable to UV rays and temperatures from -30° C to + 60° C.