PE gas

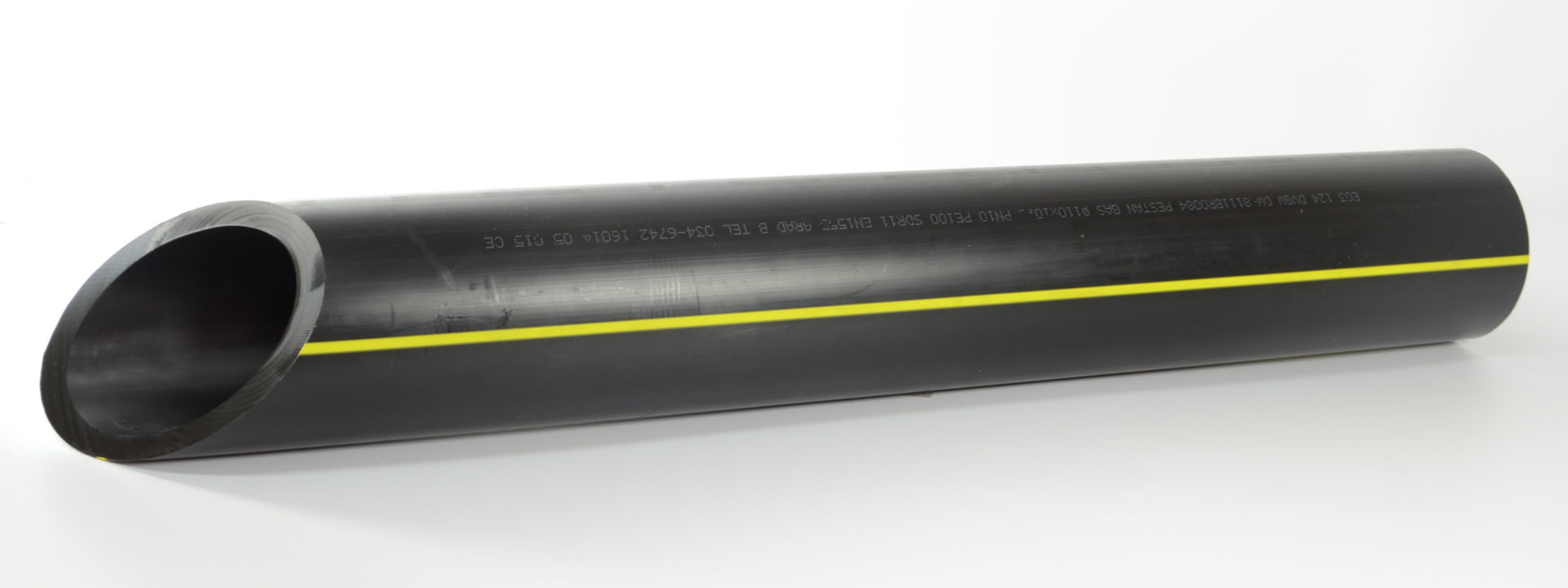

Peštan HDPE pipes for transportation of gas under high-pressure are made from high quality polyethylene PE-80 and PE-100. Pipes made of polyethylene are physiological and toxicological completely safe and extremely chemically resistant. Complete range of Peštan HDPE pipes for gas has been produced according to the EN 1555. Peštan produces pipes for gas in black color with yellow longitudinal lines, and deliver them in coils of 100m and 200m, as well as in bars of 6m, 12m, 13.5m and 16m.