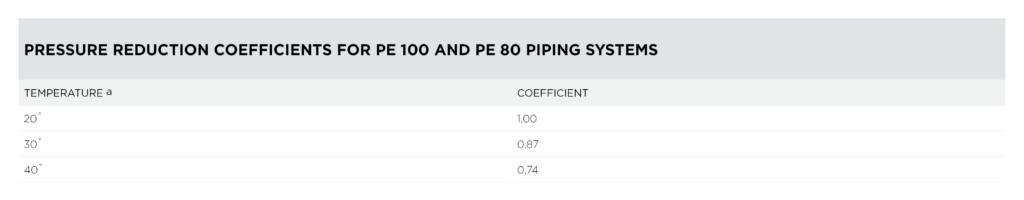

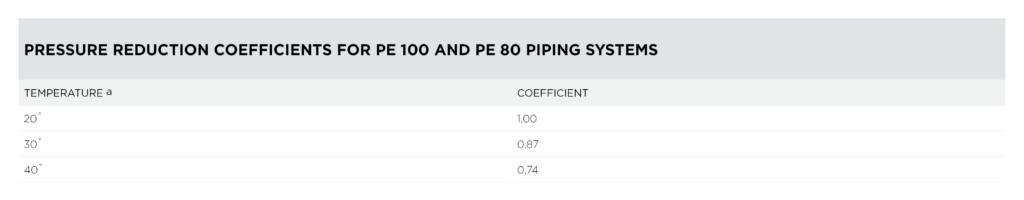

Resistance to increased temperature:

When temperatures increased exploitation (eg. Industrial use) it is necessary to correct the value using the PN -a reduction coefficient from the table:

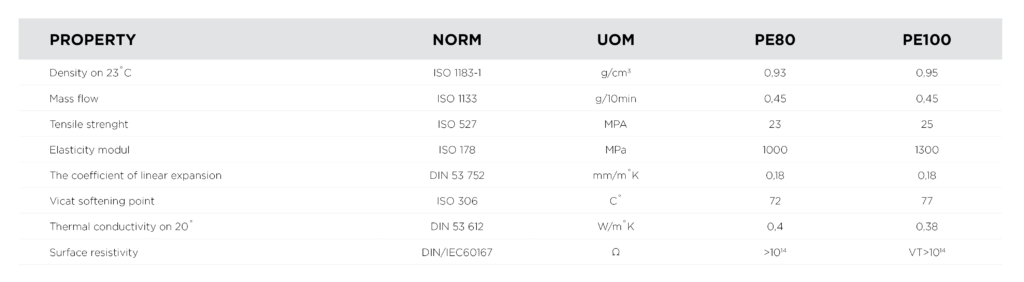

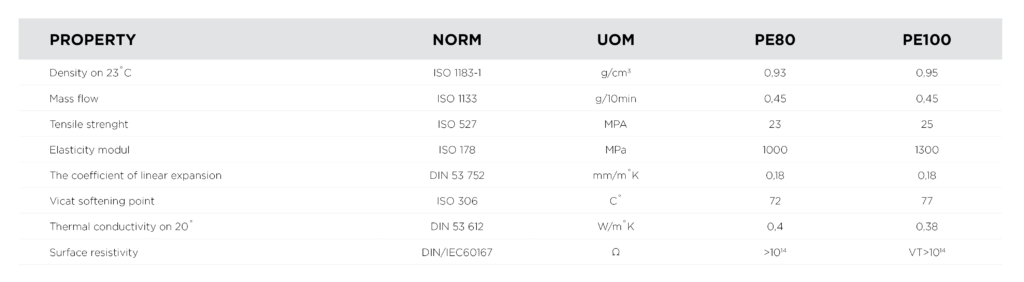

Physical properties of materials

Chemical resistance of materials

Table of chemical resistance of material viewed in the section Download

The advantage of PE 100 RC materials

Advantages of this type of pipes (PE-100 RC) relative to the pipes produced from the previous generation material (PE-100) is reflected in the fact that the RC as materials are more resistant to point loads and rapid crack propagation, and pipe manufactured from this materials are more resistant.

Connecting polyethylene water pipes made of PE100 RC is the same as connect pipes made of PE-100.

There are several ways to connect polyethylene pipes vodu. These pipes can be connected in the following ways:

1. Frontal welding

2. Electrofusion welding

3. With compression fitting (diameters up to Ø125)

4. Connecting sleeves and flanges

Electrofusion and The front welding are performed according to the guidelines of DVS 2207-1

Installation, jointing and testing of polyethylene piping is done according to applicable European standards and guidelines:

a. EN 805

b. EN 1610

c. DVS 2207-1

d. DVGW W 400-2 (A)

PAS 1075

When it comes to the usual definition of PE 100 RC, PAS 1075 (Public Available Specification) titled “Pipes made of polyethylene for alternative installation methods” published by DIN (Deutsches Institut für Normung). This publicly available specification is considered to be a complement to the existing standards and regulations.

PAS 1075 relates to increased resistance to slow crack growth pipe made of PE 100 RC used for alternative installation methods such as directed drilling, drilling in, pipe bursting, laying the pipeline without sand cribs, etc … requirements, characteristics and test procedures as well as adequate procedures for ensuring quality, regulated and secured permanent control by the authorized institutions. Polyethylene pipes, which are described in this regulation, have a significantly higher resistance to slow crack growth, as compared with conventional pipes made of PE 80 and PE 100th

Alternative ways of installation

1. Laying in narrow trenches

This is a modification of the classic pipe laying in the trench. By using short or long ditches, dig the trenches that are 100 mm wider than the pipe which is to be taken. Coiled or pre-welded pipes are laid in this passage. Significant savings can be achieved with much less the excavation volume, the less broth material (sand for substructure), and reduced operating.

2. Pipe bursting

This is an increasingly popular method for rehabilitation of existing pipelines, in places where excavation method unacceptable. With pipe bursting the existing pipe is destroyed and a new PE 100 RC pipe is pulled into the resulting hole, and provide a replacement with the same diameter pipe or with the help of destroyers, pipe diameter can increase in relation to the replacement pipe.

3. Laying plowing (plowing)

The technique was developed on the basis of the Agricultural techniques for laying and drainage. This method is used for laying pipes for water and gas routes between settlements.

4. Slip lining

Insert a small diameter PE pipes, slip-lining, the existing pipeline is one of many techniques for trenchless rehabilitation Rehabilitation-old pipeline.

With a slip lining inevitably reduce the pipe diameter, although this can be minimized by thorough cleaning of the old pipeline and selecting the largest possible diameter pipe for insertion. The smaller diameter is compensated by an improved hydraulic characteristics of polyethylene, and in some cases we have even greater throughput of the new pipeline.

5. Mole method

Mole method has become a frequently used method for trench-less setting small diameters, and can deliver significant savings in relation to the installation of pipes from the excavation. Excavation is carried out for inbound and outbound caves, and is ideal for passages mole method pipeline under the road and out of sidewalk construction, gardens and gardens, where they disrupted the excavation of soils and plants.

6. Directional Drilling

This technique has also become an established method of installation polyethylene pipes and is used for passages under the road, railway line and the river, in places where excavation difficult, expensive or impossible.

Safety factor HDPE pipes for water is 1.25

Coefficient of linear expansion of polyethylene is 1,3×10-4C-1 (0.13 mm / m ° C)